Data is the heartbeat of biotech, but if it’s not trustworthy, it’s just clutter. I heard this gem from a colleague who’s been in the regulatory game for years, and it hits home every time I tackle compliance challenges. If you’re a quality manager in biotech, you know the drill – keeping data accurate and secure isn’t just a task; it’s what keeps your work running smoothly and patients safe. In this blog, I’ll share practical ways to fix data integrity gaps that can mess things up during FDA inspections. We’ll use real-world methods, like those from Compliance Gurus, to get back on track while keeping your team confident and supported.

What Are Data Integrity Gaps and Why Do They Matter?

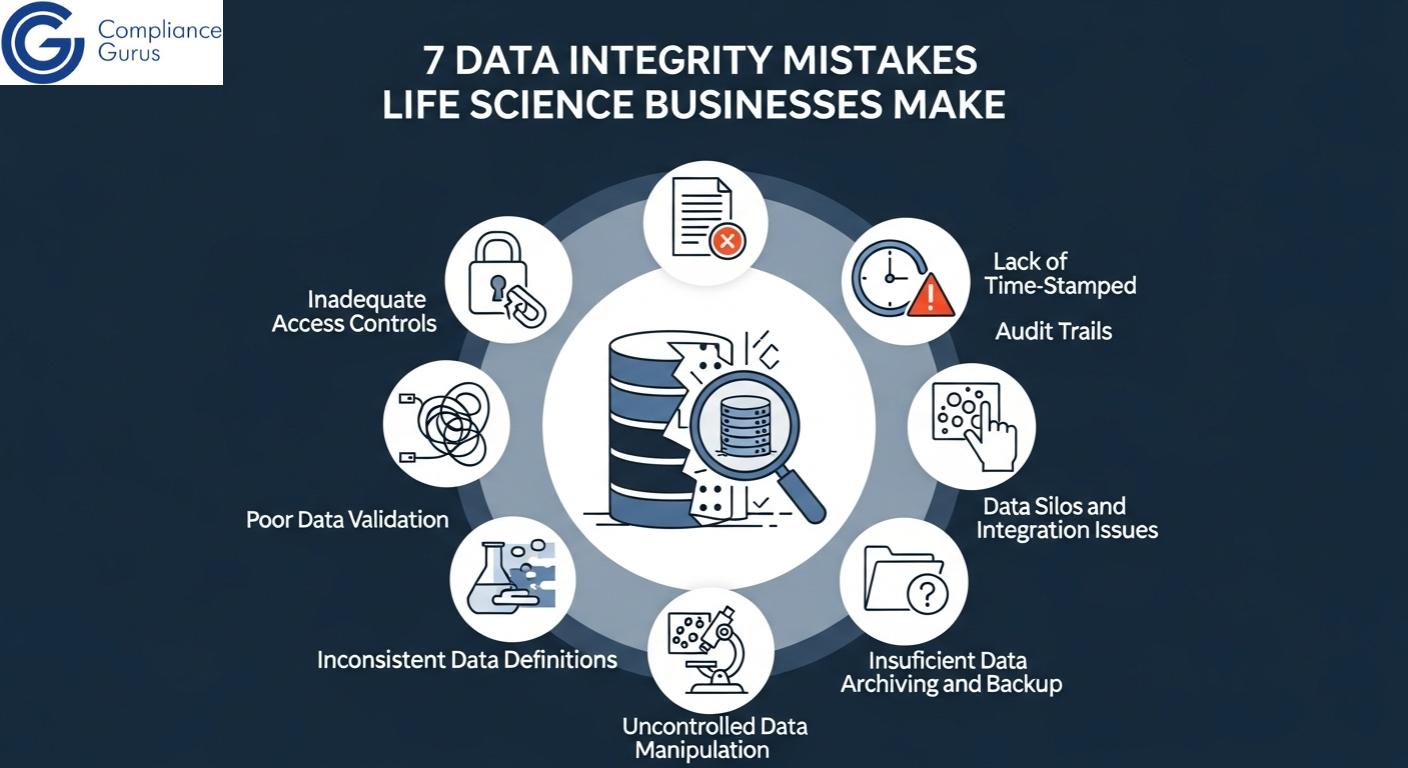

As a biotech quality manager, you’re probably juggling tons of tasks daily, from checking lab processes to making sure every report is perfect. Data integrity gaps are those weak spots where information might get messed up, lost, or handled wrong, even by mistake. Picture this: a tiny error in data entry could turn into a big problem during an audit.

These gaps often come from old systems, unclear steps, or missing checks. The FDA expects data to follow principles like ALCOA+, which means Attributable, Legible, Contemporaneous, Original, Accurate, plus extras like Complete and Consistent. If any of this slips, you risk FDA citations, like those annoying 483 observations or warning letters.

Why is this a big deal for biotech? Your work creates life-changing stuff – think vaccines or therapies. Patient safety is on the line, and so is your company’s reputation. Fixing these gaps isn’t just about avoiding fines; it’s about building trust and making your work easier. A strong data integrity setup can streamline your daily tasks, cut errors, and even speed up product development.

Understanding FDA Rules: Key Standards to Know

Diving into regulations might sound boring, but knowing them is your best defense. The FDA has clear rules to make sure data in regulated settings stays reliable. For example, FDA 21 CFR part 11 compliance deals with electronic records and signatures, ensuring they’re as trustworthy as paper ones.

Then there’s FDA guidance on computer software assurance, which pushes a smarter, risk-based way to check systems. Instead of testing everything to death, you focus on what really matters – like areas that could affect product quality or patient safety. Also, FDA software validation guidance helps you confirm your software works right, without bugs that could mess up data.

If you’re wondering how to validate software for FDA compliance, it’s about testing it carefully from start to finish. This includes writing down every step so you can show it’s all good during inspections. In biotech, where you might use complex tools like lab information systems or quality management software, getting this right keeps those integrity gaps from growing.

Finding and Checking Data Weak Spots

Before you fix anything, you need to know what’s wrong. Start by taking a close look at your current setup. Check how data is collected, stored, and shared across your team. Are there manual steps that invite mistakes? Is your software ready for regulated work?

Try using a risk-based method to spot problems. This means focusing on areas that could directly impact patient safety or product quality. Here are some things to check:

- Does your data follow ALCOA+ principles? Is every entry traceable to who made it and when?

- Are your processes clearly written out, or are there vague spots that lead to errors?

- Is your software, especially cloud-based ones like AWS or Azure, up to standard?

Building a Custom Plan to Fix Gaps

Now it’s time to get to work: create a plan to close those gaps. FDA remediation isn’t one-size-fits-all – it’s about making solutions that fit your specific needs. If you’ve gotten an FDA citation, like a 483 or warning letter, you need to act fast and smart.

Start by reviewing the FDA’s findings with your team to understand what went wrong. Then, build a plan that tackles each issue directly. This could include:

- Gap analysis: Figure out exactly where things broke down and how to fix them.

- Custom strategies: Use FDA guidance on computer software assurance to focus on risks instead of over-testing.

- Clear steps: Roll out changes with deadlines and assign roles so everyone knows their job.

For biotech managers, this often means validating software systems. If you’re using cloud platforms, make sure they’re compliant in regulated settings. The goal is to not just fix the problem now but set up systems that stay strong for the long haul. Think of it as building a shield to handle future challenges with ease.

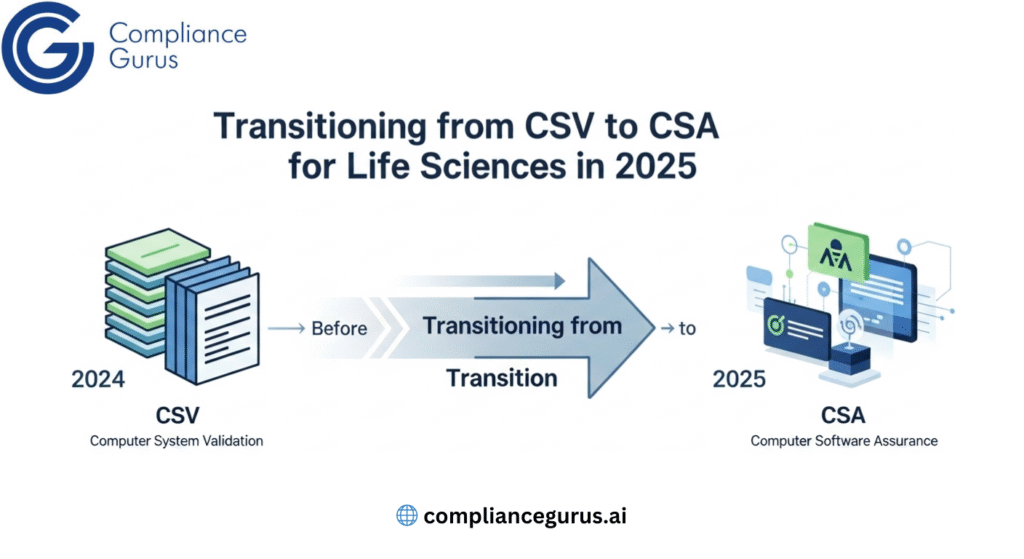

Using Computer System Validation and Assurance

A big part of fixing data integrity is getting your software right. That’s where Computer System Validation (CSV) and Computer Software Assurance (CSA) come in. CSV is the classic approach – lots of testing and paperwork to prove your systems work as they should from start to finish.

CSA is newer and more efficient. It uses a risk-based approach, cutting down on extra documents and tests. For biotech, this means you can validate complex tools like ERP systems or clinical software without slowing down your work.

Here’s a quick look at how they differ:

- CSV Focus: Thorough checks from design to retirement, ensuring full compliance with rules like 21 CFR Part 11.

- CSA Edge: Smarter testing based on risks, leading to quicker validations and less work for your team.

In practice, mixing both gives great results. Use CSA for low-risk areas to save time, and apply CSV’s rigor to critical data paths. This combo keeps data integrity solid while keeping your biotech projects moving.

Practical Tips for Biotech Quality Managers

Having helped teams through these challenges, here are some hands-on tips to make FDA remediation easier:

- Train your team often: Keep everyone in the loop on data integrity basics. Short, real-world examples beat long talks.

- Pick tools wisely: Use validated software that supports ALCOA+ naturally, cutting down on mistakes.

- Check regularly: Don’t wait for audits – set up periodic reviews to catch issues early.

- Work together: Quality isn’t just your job; get IT, R&D, and operations involved for a complete picture.

Some common mistakes to avoid:

- Skipping risk checks can lead to too much or too little testing.

- Ignoring global rules if your products go overseas – FDA isn’t the only one watching.

- Forgetting cloud validations, SaaS is great, but it needs proper checks.

By working these into your routine, you’ll not only fix gaps but create a workplace where compliance feels easy, not forced.

Keep up with changes in FDA software validation guidance to stay ahead. This forward-thinking approach turns compliance from a task into a strength.

Closing Thoughts: Your Path to Better Compliance

We’ve covered a lot – from finding data integrity gaps to building strong remediation plans. As a biotech quality manager, you’re key to protecting not just data, but the innovations that change lives. By using these tips, like focusing on risk-based validations and tailored plans, you can handle FDA challenges with less stress and more success.

Ready to take things up a notch? The team at Compliance Gurus specializes in how to validate software for FDA, EU, and MHRA compliance, with years of experience in data integrity and remediation. We can help you assess, plan, and put solutions in place that fit your biotech needs perfectly. Reach out now!