Real innovation isn’t just about keeping up – it’s about choosing what truly matters for patient safety and business growth.

As life sciences companies move deeper into the world of automation, cloud services, and digital transformation, old approaches to compliance are giving way to something both smarter and more relevant for today’s competitive reality.

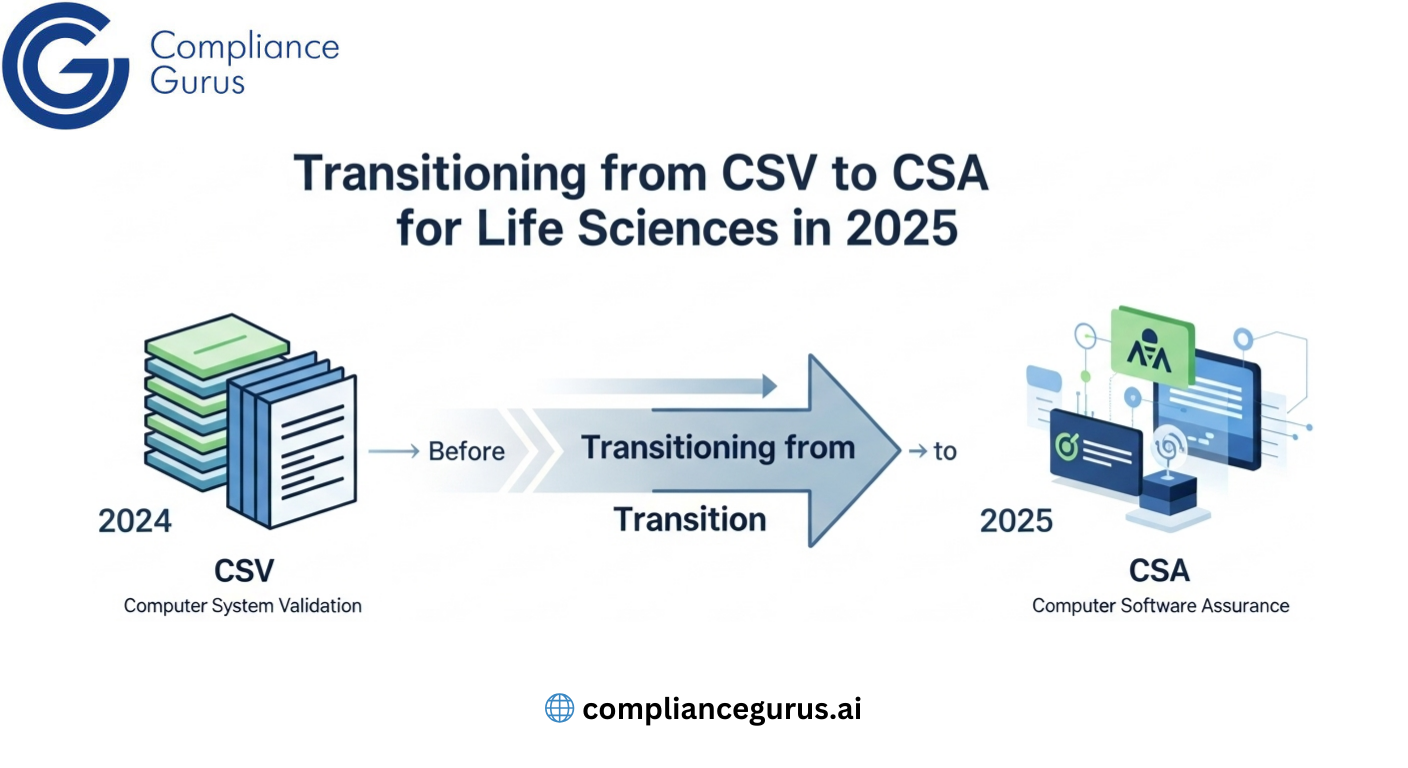

This is not just an inside baseball moment for regulatory affairs – it’s a broad evolution impacting everyone involved with medical device manufacturing, quality systems, biotech, and pharma. If the letters CSV and CSA sound like alphabet soup, now’s the time to get clear: because forward-looking organizations are making the leap, and for good reasons. This guide explains the pivotal shift from Computer System Validation (CSV) to Computer Software Assurance (CSA), grounded in the lessons and perspective from the latest FDA draft guidance and influential analysis offered by the FDLI.

Change Is Not Just a Trend – It’s a Necessity

Most life sciences manufacturers and their suppliers have built their operations around computerized systems: batch record software, document management platforms, laboratory information suites, environmental monitoring, complaint management tools, and more. The value these technologies offer grows bigger every year, touching almost every step from design through delivery.

- Global market stats show medical device cloud solutions nearly doubled in only a few years, with a clear surge in automation and simulation technologies supporting product quality and safety.

- The FDA’s compliance rulebook (GxP, 21 CFR Part 11, and 21 CFR Part 820) requires validation for any system with direct or indirect impact on patients and products. As more systems shift to SaaS and cloud, validation demands have stretched resources to the breaking point.

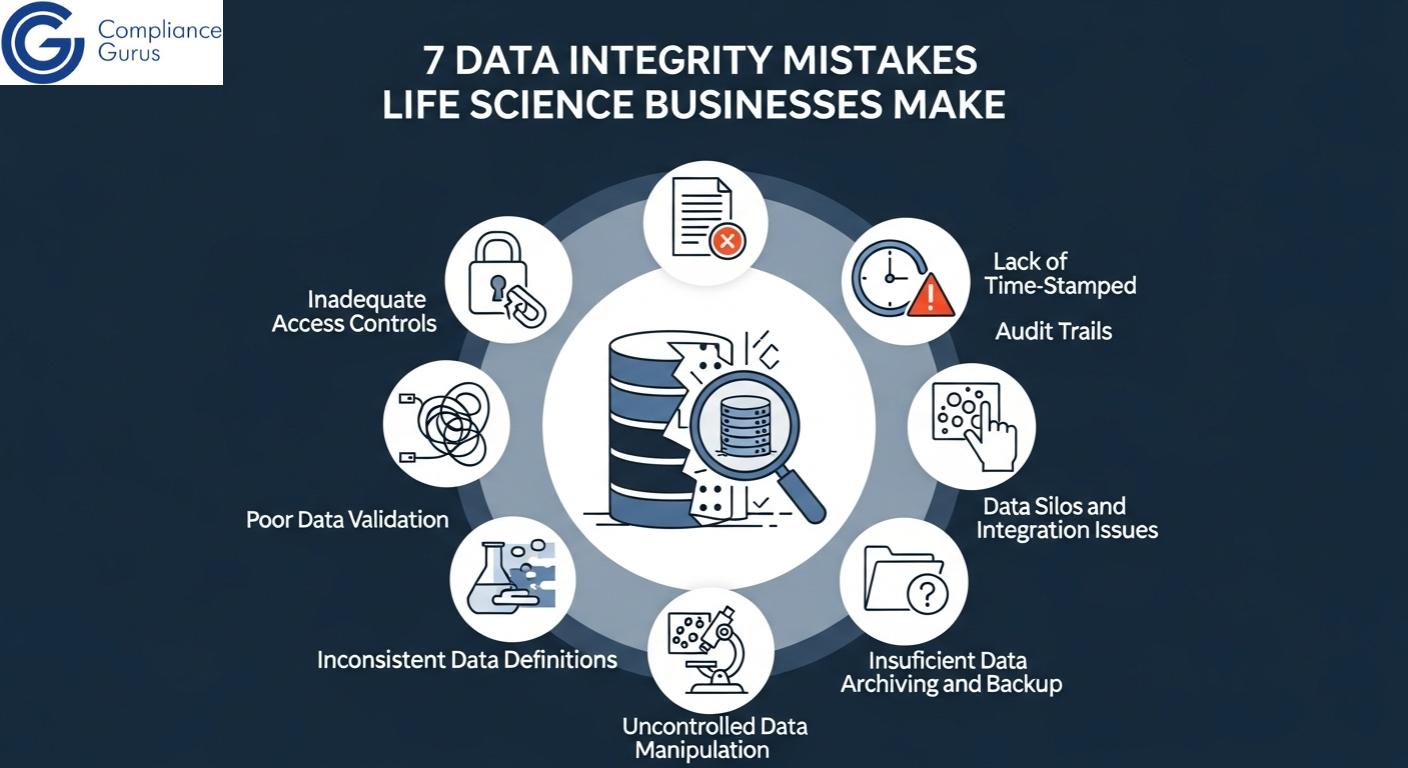

For over two decades, Computer System Validation (CSV) has been the answer. Yet, traditional CSV is far from perfect. Too much time gets swallowed by repetitive manual documentation, screenshotting every test, “audit-proofing” things for inspectors, and often missing the forest for the trees when it comes to real assurance.

The FDA’s New Approach: CSA as a Practical Solution

On September 23, 2025, the FDA published the Final guidance called Computer Software Assurance for Production and Quality System Software. This was a much-awaited update, addressing a decade’s worth of feedback from industry stakeholders who needed modern, efficient, and agile compliance solutions.

- CSA is defined as a risk-based approach, establishing confidence that software is fit for its intended use, with a proportional level of assurance effort based on risk to product and patient safety.

- The guidance urges manufacturers to avoid outdated “test-everything” methods, giving them flexibility and ownership over their validation strategies, with a spotlight on critical thinking, automation, and the right-sizing of evidence.

This means regulator and industry both want the same thing: robust software quality, data integrity, and patient safety – delivered with efficiency and clarity, not burdensome paperwork.

CSV vs CSA: Breaking the Mold

Let’s get clear on the main differences shaping this transition.

| CSV (Traditional) | CSA (Modern Approach) |

| Blanket, paper-heavy testing | Risk-based, lean documentation |

| Focused on audit-proof compliance | Focused on real-world assurance & efficiency |

| Delivers technical debt (slow upgrades) | Supports Agile/cloud; stays “in control” |

| Reactive, error-prone | Proactive, informed by vendor rigor |

| Quality comes in late | Quality engaged early – less rework |

- CSV usually means 80% time spent on form-filling, screenshots, and scripts, with just 20% for actual assurance and verification.

- CSA flips the model: 80% of resources go to risk-based analysis, vendor qualification, and critical-thinking activities, and only 20% to documentation/testing.

It’s no exaggeration to say this better matches how most life sciences businesses work now: using commercial and SaaS solutions, updating frequently, dealing with global inspection pressures, and running lean teams due to staffing shortages.

Key Features of CSA: The Four-Step Process

FDA’s CSA draft lays out an actionable process for life sciences organizations. Its pillars are:

- Identify Intended Use: Clearly define what each system and feature must accomplish in production and quality settings.

- Assess Risk of Failure: If the software fails, what’s the impact on safety and product quality? Analyze the likelihood and detectability of failures.

- Choose Assurance Activities: Pick testing and documentation strategies reflecting risk – more for critical functions, less for simple/low-risk features.

- Gather Evidence: Keep records proving the system works as intended, focusing on clarity and completeness, not volume or redundancy.

The approach is explicitly Agile-compatible and cloud-friendly. It matches iterative development, allowing validation activities to keep pace as upgrades roll out – no more scrambling to catch up after every SaaS release.

Rethinking Validation Testing: Risk, Vendor Qualification, and Smart Choices

Traditional CSV puts all risk on the life sciences company – every SaaS upgrade meant re-validating from scratch. Now, CSA shifts the burden: quality and testing activity is distributed between clients and vendors. Companies qualifying suppliers through thorough audits may “take credit” for vendor proofs, avoiding duplicate work.

Here’s how CSA enables smarter choices:

- Scripted Testing: Reserved for complex, patient-impacting functions or high-risk features.

- Unscripted or Ad-Hoc Testing: Used for basic functions with low risk, saving time and effort.

- Validation Automation Platforms (VAPs): Automate protocol workflows, reporting, electronic records, and inspection dashboards – becoming a critical backbone for CSA-ready firms.

Vendor qualification now plays a starring role. Audits ensure supplier QA teams, software quality, and validation documentation meet regulatory standards. This mechanism doesn’t just satisfy CSA guidance, it supports a lifecycle approach – maintaining a “state of control” through regular reviews and upgrades.

Inspection Readiness in a CSA World

One source of anxiety is always inspection. The good news? CSA thinking makes audits smoother, more logical, and less stressful.

- FDA says documentation should show enough evidence that risk-critical functions work as intended for their contex – no more, no less.

- Key deliverables in a CSA project may include:

- A validation plan showing scope and rationale

- Risk assessment reports

- Test objectives and results (installation, operational, performance, and acceptance)

- Sign-off records of test personnel

- Summary reporting, conclusions, and statements regarding production suitability.

Crucially, QA needs to be engaged up front – taking part in risk reviews, planning, and ongoing assessments, not just signing off at the tail end. Automation and digital records (audit trails, system logs, etc.) are now preferred by regulators instead of endless screenshots.

Modern Compliance: CSA Is Built for Tomorrow’s Systems

We’re in an era of fast-moving upgrades, increasingly complex applications, and globalized inspection standards. CSA isn’t a luxury – it’s the new foundation for sustainable compliance in all regulated environments.

- Automation tools and platforms manage protocols, evidence, reporting, and dashboards – making inspection readiness simpler and less error-prone.

- Companies can “right size” their validation effort, saving resources and staying up to date even as vendors push regular SaaS updates.

- The FDA, ISPE GAMP 5, and the Case for Quality programs all endorse risk-centered, lifecycle compliance.

CSA gives organizations flexibility. With clear strategies, strong documentation, and qualified suppliers, they can show fit-for-purpose assurance, protect patient safety, and meet regulatory demands – without burning out teams or budgets.

How to Move Forward: Your CSA Adoption Roadmap

Adopting CSA is a practical journey, not a leap. Here are actionable steps for leading the transition:

- Map Your Systems

Identify which applications drive patient safety, product quality, or regulatory compliance, and rank them by risk level.

- Educate Your Teams

Invest in training – critical thinking in validation, risk assessment, and supplier qualification are core to success.

- Evaluate and Qualify Vendors

Use robust supplier audits to ensure confidence in vendor documentation and system quality.

- Integrate Automation

Choose validation workflow platforms to automate reporting, evidence management, and inspection prep.

- Engage QA Upfront

Make quality teams key partners from project beginnings – not just passive sign-offs at the end.

- Prepare Smart Documentation

Focus records on what’s needed for regulatory assurance – not just what’s always been done.

- Embrace Iterative Review

Update risk assessments and assurance activities as systems evolve with new releases and upgrades.

Your CSA Checklist: Essentials for Life Sciences Success

- Adopt risk-based, flexible testing and documentation – it’s not “test everything” anymore.

- Leverage vendor validation activities wherever possible.

- Use digital recordkeeping and automation platforms for workflows and evidence.

- Put product/patient safety and data integrity at the center of every decision.

- Empower Quality expertise from day one, not after the fact.

Final Words: CSA Is Your Pathway to Confident Compliance

Shifting from CSV to CSA isn’t just about keeping up with regulations – it’s about working smarter, not harder. Life sciences firms that embrace CSA are setting themselves up for long-term compliance, faster adoption of new technologies, and stronger data integrity. The benefits ripple across quality teams, IT departments, and executive leaders every day. FDA recognizes the need for companies to move forward – and offers the guidance flexibility needed to do so well.

Contact Compliance Gurus now and see how straightforward, practical consultation can drive a clear, confident path to CSA. Compliance doesn’t have to be a burden – it can be an engine for innovation.